1. Description:

The C-KT series sic-ceramic centrifugal pump developed by Tech-Macro has the characteristics of high hardness, super wear resistance and corrosion resistance, high temperature resistance, etc. It is suitable for transferring strong corrosion and strong abrasive fluids, such as mud, desulfurization slurry and wastewater, coal slurry, fine-grained silica sand water mixture, chemical slurry, etc.

Typical Application:

● FGD(Flue Gas Desulphurization) process

● Zero Liquid Discharge process

● Chemical industry

● Other highly corrosive and abrasive fluids

2. Features:

● High efficiency leads to low energy costs; long service life; low wear low operating cost.

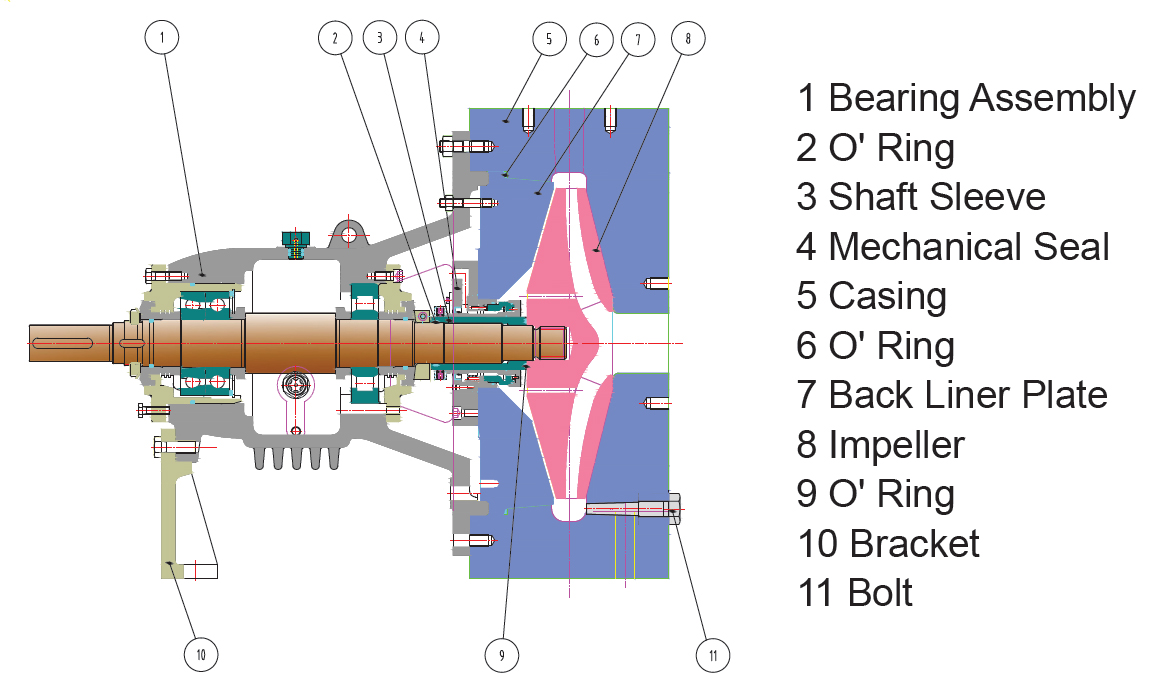

● Back pull-out structure ensures easy maintenance (the complete rotating assembly can be removed while the casing remains on its position and then no need to dismantle the discharge and inlet pipeline) . With impeller release collar, no special tools required during disassembly, ensure no damage to impeller and shaft.

● Efficient impeller, which is made of abrasion and corrosion resistance ceramic.

● Cylindrical roller bearings on pump end, and two disc angular contact ball bearings in back-to-back arrangement are mounted to the driving end, which improves the bearings working condition and extend the service life of the bearings.

● The C- KT series SiC ceramic pumps are designed to be connected directly driven.

● Integrating mechanical sealing ensures the reliability of the pump.

● The wet end parts are replaceable or repairable, reduce the using life-Cycle-Cost.

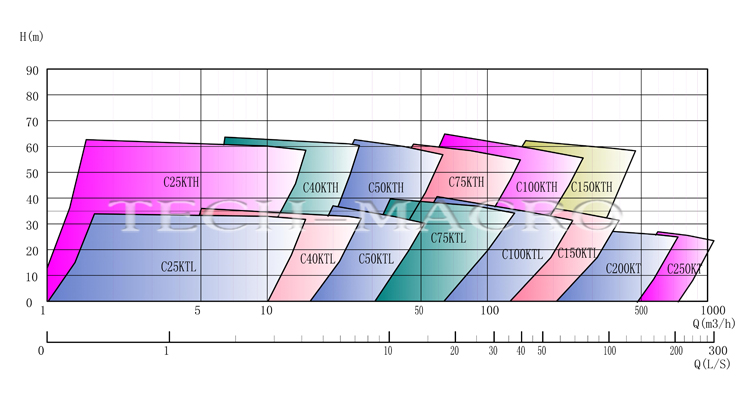

1. Pump Specification:

Discharge Diameter: 25~250mm

Flow Capacity: 10~1000m3/h

Head: up tp 65m

2. Material:

|

Materials Specification |

|

Materials |

SiC (Silicon carbide) Ceramic |

|

Composition |

Pherical superhard ceramic, ceramic powder, metal carbide and quartz particles combined by two-component thermosetting adhesive |

|

Mohs Hardness |

9~9.5 |

|

Working temperature |

-40℃~110℃ |

|

Acid-alkali resistance |

PH 0~14 |

|

Application range |

It can be used for the conditions of any chlorine ion concentration. |

3. Performance Chart: