Product hotline

0086-311-89809027

Product hotline

0086-311-89809027

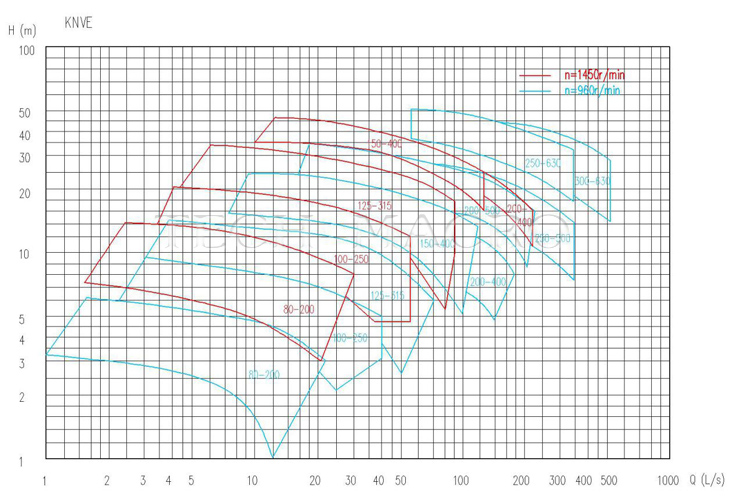

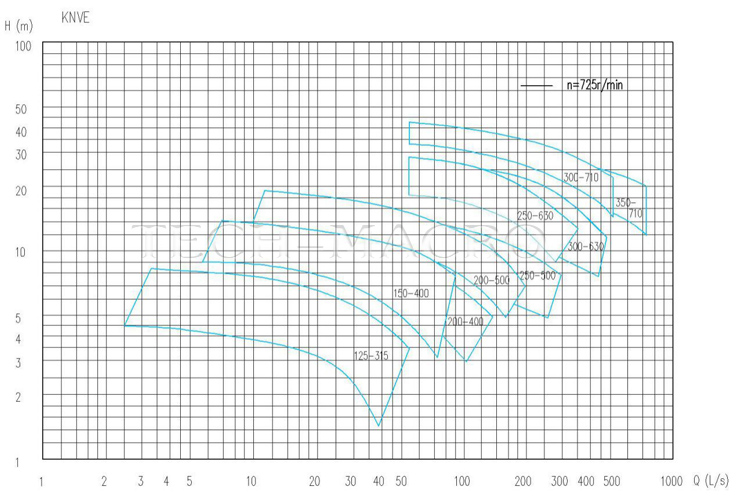

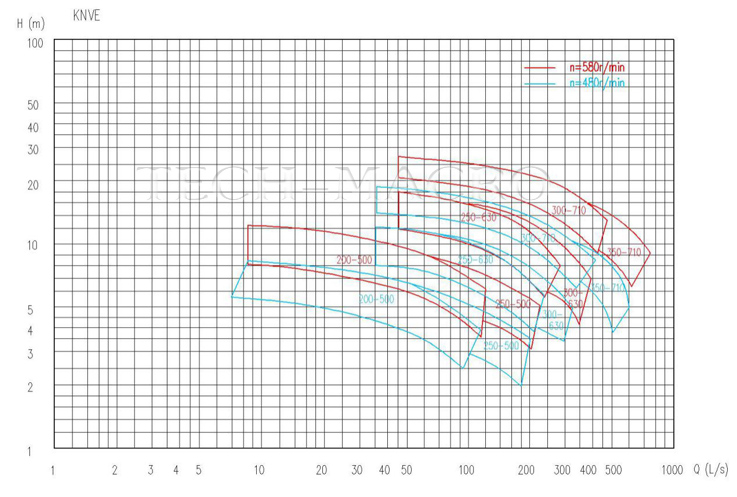

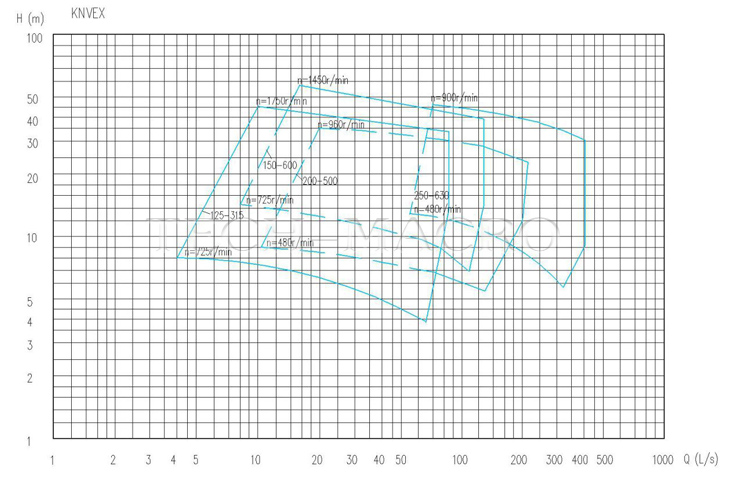

Model:KNV Series

Head: 5~50m

Capacity: 4~2500 m³/h

Pump type: Non-clogging centrifugal pump

Media: Sewage, exhaust water, sludge, fruits, potatoes, beets, corns, cereals, fish etc.

Material: Metal

| Materials Options | ||

| Construction | Standard | Optional |

| Casing |

Grey cast iron, ductile cast iron, nickel cast iron; Stainless steel (SS304, SS3016…); High chrome alloy (A05, A49, A61……); |

The material adopted is usually based on the detailed application, or could be according to the customer’s requirements. |

| Other wet end parts (Impellers) |

Grey cast iron, ductile cast iron, nickel cast iron; Brass, bronze; Stainless steel (SS304, SS316…); High chrome alloy (A05, A49, A61……); |

|

| Shaft |

Carbon steel(1045), Stainless steel(2Cr13, 3Cr13) |

|

| Bracket | Carbon steel | |

|

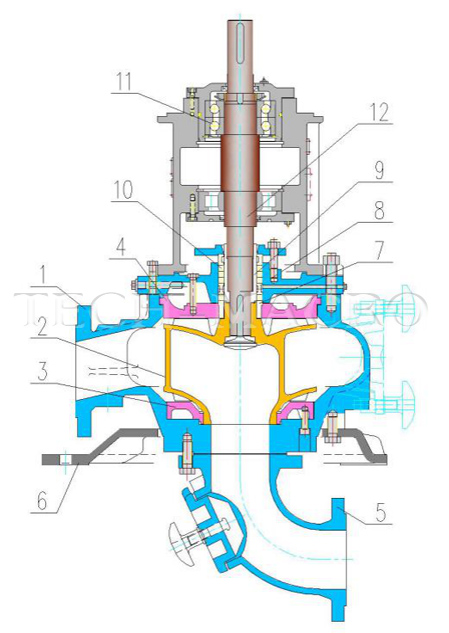

Pit Installation 1 Pump casing 2 Impeller 3 Throat bush 4 Back liner 5 Suction elbow 6 Installation plate 7 Packing bush 8 Latern ring 9 Shaft sleeve 10 Packing 11 Bearing 12 Shaft |

|

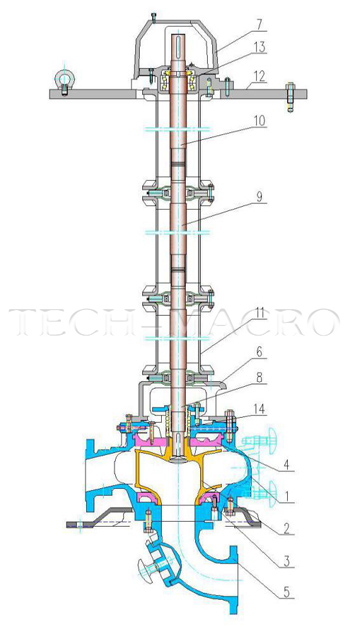

Dry installation 1 Pump casing 2 Impeller 3 Throat bush 4 Back liner 5 Suction elbow 6 Supporting base 7 Motor supporter 8 Shaft 9 Intermediate shaft 10 Driving shaft 11 Intermediate pipe 12 Installation plate 13 Bearing 14 Packing box |

TELEPHONE: 0086-311-89809027

Email(for Project Enquiry): techmpump@163.com

Email(for General Enquiry): cnpumpru@163.com

Add: No.55 Kunlun Great Street Shijiazhuang City PRC

Fax:0086-311-89809027