1. Description:

The KG(H)dredge pump(or called as sand&gravel pump)is single-stage, single-suction, single-casing horizontal slurry pump, and the KGH pumps are high head ones. The pumps are designed for continuously transferring strong corrosive big-solid-contained slurry which the common slurry pump cannot transfer. They are widely used in mining, explosive-sludge in metal melting, dredging in dredger, etc.

Typical Application:

● Dredging in dredger

● River channel dredging

● Stone material processing factory

● Transferring power plant ash

● Delivering furnace clinker in iron works

2. Features:

● Abrasion-resistance, corrosion-resistance; large capacity; wide flow channel; light weight; good performance of NPSH; easy maintenance; anti-clogging.

● Special clamping device of the jointing for pump body and pump cover enables the pump discharge point to any direction.

● The wet parts , including impeller, frame plate, throatbush, frame plate liner insert, all adopt anti-corrosive alloy cast iron or steel.

● The pump consists of pump head, seal assembly, bearing assembly and frame. The bearing assembly is lubricated by grease.

● The pump can be driven by V-belt, coupling directly or by reducer.

● Packing seal, expeller seal and mechanical seal are all available for the pump.

1. Operating Limits

● Inlet diameter:6-32 inch(150-812 mm)

● Discharge diameter:4-28 inch(100-711 mm)

● Flow capacity:36-14400 m3/h

● Head :5-90 m

2. Material(Wet-parts)

|

Materials Options |

|

Construction |

Standard |

Optional |

|

Wet end parts (Casings, Impellers) |

High chrome alloy (A05, A08, A09, A61……)

|

The material adopted is usually based on the detailed application, or could be according to the customer’s requirements. |

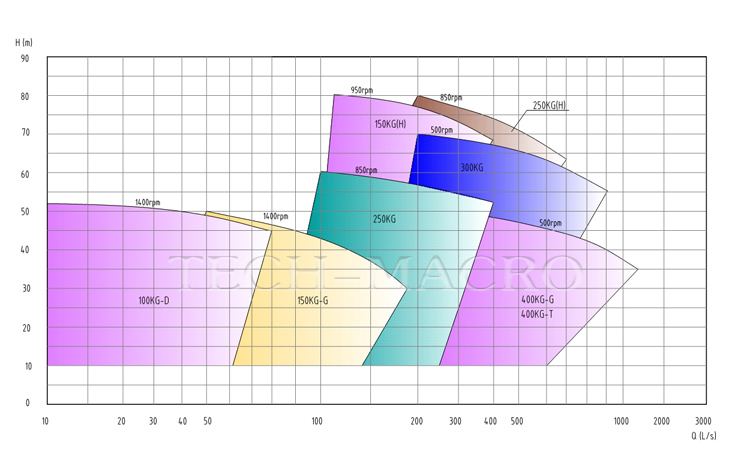

3. Performance Chart

Note: Approximate clear water performance, and only used for primary model choice.

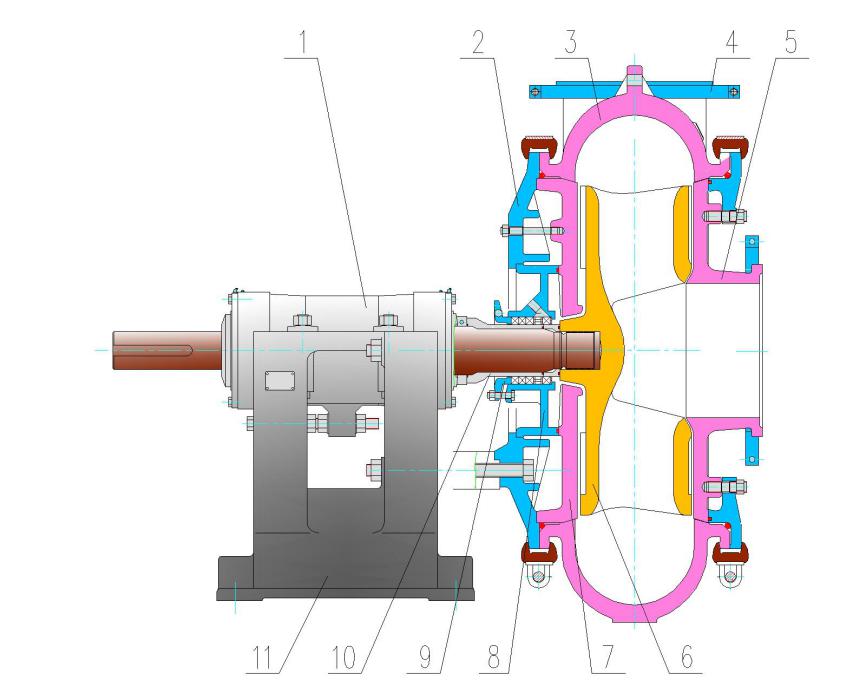

Structure

KG Series

1 Bearing assembly 2 Joint plate 3 Frame plate 4 Split discharge flange 5 Throat bush 6 Impeller 7 Back liner 8 Sealing box 9 Packing gland 10 Shaft sleeve 11 Bracket |