Product hotline

0086-311-89809027

Product hotline

0086-311-89809027

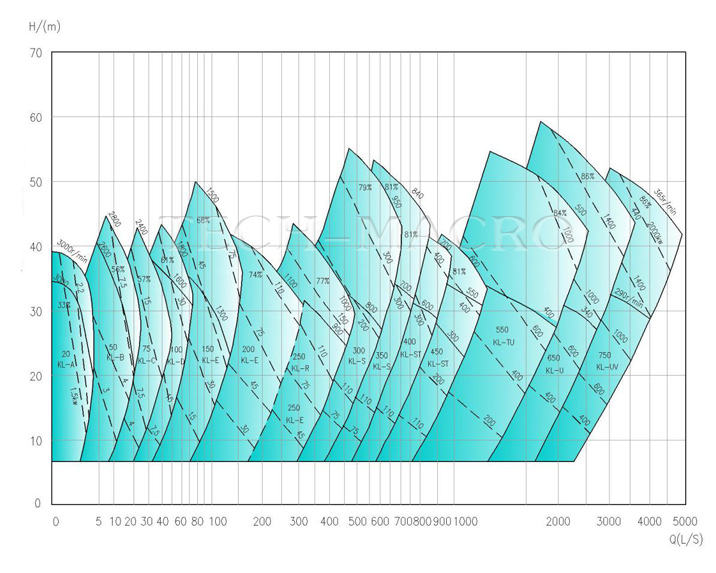

Model:KL Series

Head: 5--68 m

Capacity: 0.36--21600 m³/h

Pump type: Horizontal centrifugal

Media: Slurry

Material: Metal, rubber, ceramic,etc

| Materials Options | ||

| Construction | Standard | Optional |

| Wet end parts (Liners,Impellers) |

High chrome alloy (A05, A07, A08, A09, A11, A49, A33, A61……); Natural rubber (R26, R24, R55......); Synthetic rubber(S01, S12, S21, S42......) Composite ceramics Polyurethane |

The material adopted is usually based on the detailed application, or could be according to the customer’s requirements. |

|

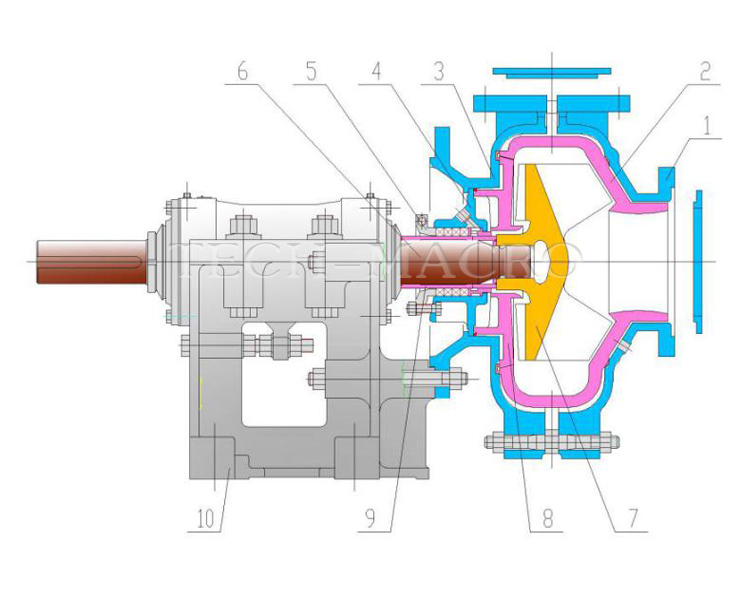

KL series

1 Throat Bush 2 Volute Liner 3 Pump Body 4 Packing Box 5 Packing Gland 6 Shaft 7 Impeller 8 Rear Liner 9 Shaft Sleeve 10 Frame

|

TELEPHONE: 0086-311-89809027

Email(for Project Enquiry): techmpump@163.com

Email(for General Enquiry): cnpumpru@163.com

Add: No.55 Kunlun Great Street Shijiazhuang City PRC

Fax:0086-311-89809027