1. Description:

Type KH pump is heavy-duty single-stage single-suction high-head horizontal centrifugal slurry pump. This type of pump has larger volume and separated wear-resistant layer and bearing layer. It is suitable for transferring high head slurry at high pressure, mostly used for long distance transporting.

Typical Application:

● Iron, cooper or phosphorus mineral processing

● Cyclone feeding

● Removing ash in power plant

● Flue gas desphurization in power plant

● Flushing steel mill blast furnace cinder

● Removing ash in power plant

● Ball grinding mill ore discharging

● Other wear-resistant and anti-corrosive working conditions

2. Features:

● High efficiency, wear resistant, stable performance, interchangeability of parts; high head; energy saving.

● Replaceable wear-resistant metal liners, impellers&volute liners are made of wear-resistant metal(such as A05,A49,and other high chrome metal). The bearing layer and the wear-resistant layer can be separated.

● High efficiency impeller of large diameter and slow rotation speed ensures the pump with long wear parts using life and low operating cost.

● Bearing assembly use cylindrical structure, adjusting the space between impeller& front liner easily, being removed completely when being repaired. Grease lubrication.

● Shaft seal could use the packing seal, expeller seal and mechanical seal. One pump also can be use expeller seal accompany with packing.

● The discharge outlet can be positioned to 8 directions at intervals of 45 degrees.

● This pump can be installed in multistage series to meet the delivery for long distance.

● Drive types: direct coupling drive(DC), V belt drive (CR, CV, ZV, CL), etc.

1. Operating Limits:

● Outlet Diameter:25 to 150 mm (1--6 inches)

● Flow Capacity:3.6--900 m3/h

● Head:12--105 m

2. Materials:

|

Materials Options |

|

Construction |

Standard |

Optional |

|

Wet end parts (Liners,Impellers) |

High chrome alloy (A05, A07, A08, A09, A11, A49, A33, A61……);

Composite ceramics |

The material adopted is usually based on the detailed application, or could be according to the customer’s requirements. |

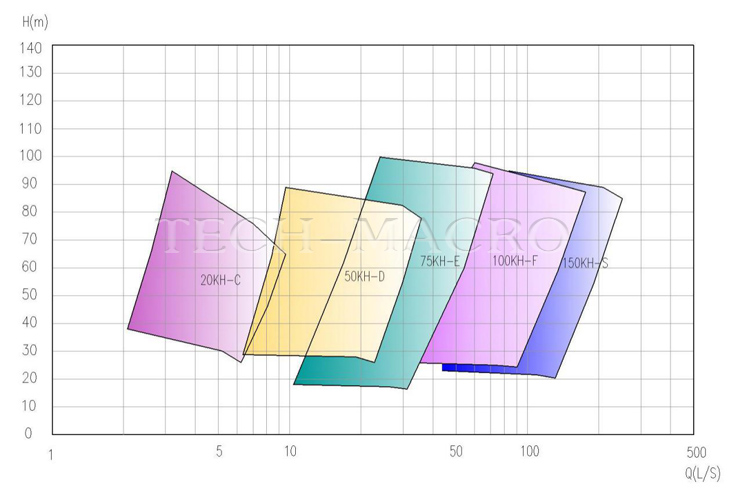

3. Performance Chart:

Note: Approximate performance of clean water and only for primary model choice.

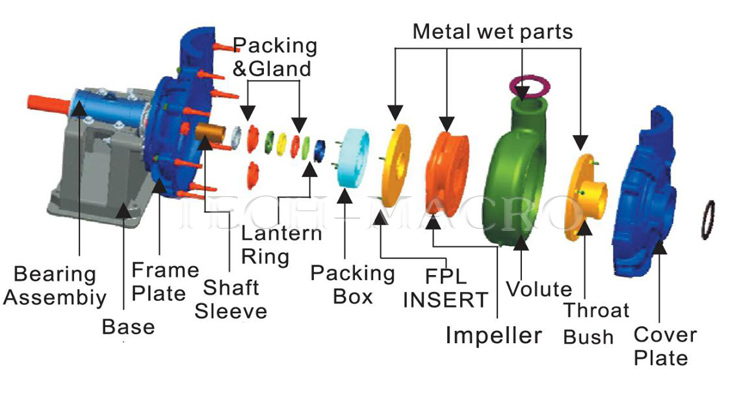

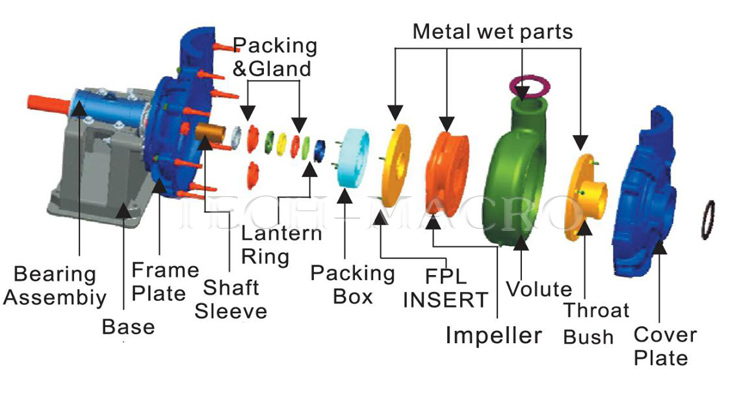

Structure