Product hotline

0086-311-89809027

Product hotline

0086-311-89809027

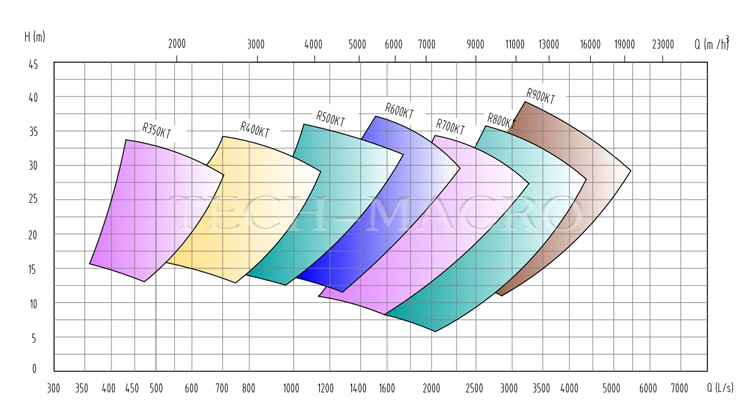

Model:KT Series

Head: 10--75 m

Capacity: 260--4900 l/s=930--17650 m³/h

Pump type: Horizontal centrifugal pump

Media: Slurry

Material: Metal, rubber

| Materials Options | ||

| Construction | Standard | Optional |

| Frame plate, cover plate, joint plate | Ductile cast iron | The material adopted is usually based on the detailed application, or could be according to the customer’s requirements. |

| Impeller, suction cover/ front liner | High chrome alloy (A49 abrasion & corrosion resistance material); | |

| Frame plate liner and cover plate liner, back liner |

Anti-abrasive, anti-corrosive rubber : natural rubber( R26, R38, R66........) or synthetic neoprene rubber (N22.....); |

|

|

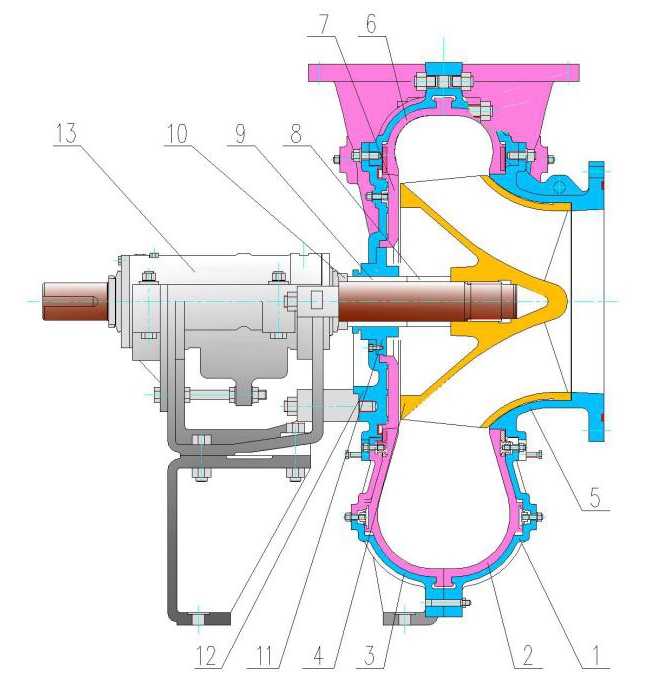

R-KT series 1 Cover plate 2 Cover plate liner 3 Frame plate 4 Impeller 5 Suction cover 6 Frame plate liner 7 Back liner 8 Front shaft sleeve 9 Shaft sleeve 10 Impeller release collar 11 Mechanical seal 12 Joint plate 13 Bracket |

TELEPHONE: 0086-311-89809027

Email(for Project Enquiry): techmpump@163.com

Email(for General Enquiry): cnpumpru@163.com

Add: No.55 Kunlun Great Street Shijiazhuang City PRC

Fax:0086-311-89809027