1. Description

KN series non-clogging water pumps are the single stage, axial suction and cantilever non-clogging centrifugal pump. There are four types of impeller for selection.‘B’ impeller - closed non -clogging impeller;‘D’ impeller -closed multi-vane impeller;‘E’ impeller -open impeller;‘Z’ impeller -free-flow impeller.

Typical application

It is specially used for the city water supply, the sewage and effluent treatment, chemical, iron&steel industries and the paper,sugar & caned food industries. It can deliver all kinds of sewage, clear water, seawater, bittern water, waste water and sludge so that it can be used in water supply plant , sewage treatment works, breweries, mines as well as the chemical and construction industries. Type KN pump normally is suitable for delivering the neutral media( PH value is 6-8 about ). For the application of corrosive fluid and other special requirements, please quote this information when making order.

2. Features

● High efficiency, Non-clogging, Reliable operation, Little vibration, Low noise, Easy maintenance.

● The series KN pump is supplied with 4 kinds of impeller for selection.

‘B’ impeller-closed non-clogging impeller.

For clear water, the sewage and fluids containing solids and sludge which do not liberate gas.

‘D’ impeller-Closed multi-vane impeller

For clear water, the fluid containing slight suspension such as treated sewage, screen water, pulp water,sugar juices,and so on.

‘E’ impeller-Open impeller

Same applications as ‘D’ impeller but also including fluids containing air.

‘Z’ impeller-Free-flow impeller

For fluids containing coarse solids liable to bunch or plait(such as long fiber admixtures, sticky particles and so on)and fluids containing air.

● Shaft seal:

Gland seal:there are two kind of design:standard’s and high-temperature’s.

The high temperature type should be used when the temperature is higher than 90℃.

The stuffing box of this type can be cooled in order to be suitable for the transporting duty in high temperature.

Mechanical seal: It also can be used for the application where leakage is not allowed.

● Drive:

In general, they are directly coupled. Type are also indirectly coupled with belt, the range of drive ratio is from 1:1 to 1:2.

1. Operating limited

Inlet Diameter:2.5~20 inch (65~500mm)

Discharge Diameter: 1.5~20 inch (40~500mm)

Flow Capacity: 8~4500m3/h

Head: 1~100m

2. Material:

|

Materials Options |

|

Construction |

Standard |

Optional |

|

Casing |

Grey cast iron, ductile cast iron, nickel cast iron;

Stainless steel (SS304, SS3016…);

High chrome alloy (A05, A08, A09, A49, A61……); |

The material adopted is usually based on the detailed application, or could be according to the customer’s requirements. |

|

Other wet end parts (Impellers) |

Grey cast iron, ductile cast iron, nickel cast iron;

Brass, bronze;

Stainless steel (SS304, SS316…);

High chrome alloy (A05, A08, A09, A49, A61……); |

|

Shaft |

Carbon steel(1045),

Stainless steel(2Cr13, 3Cr13) |

|

Bracket |

Carbon steel |

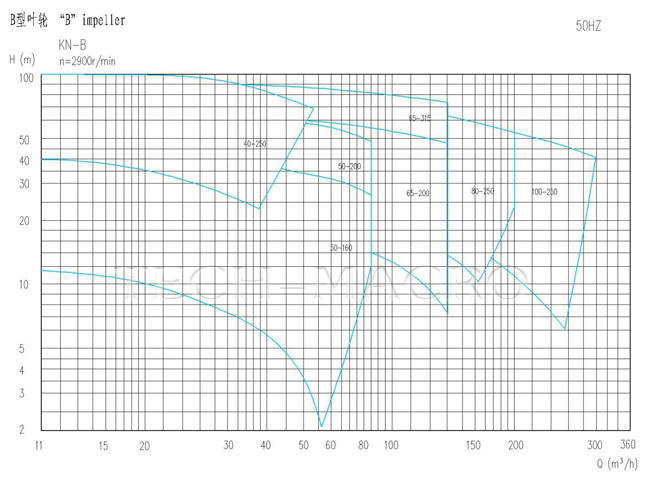

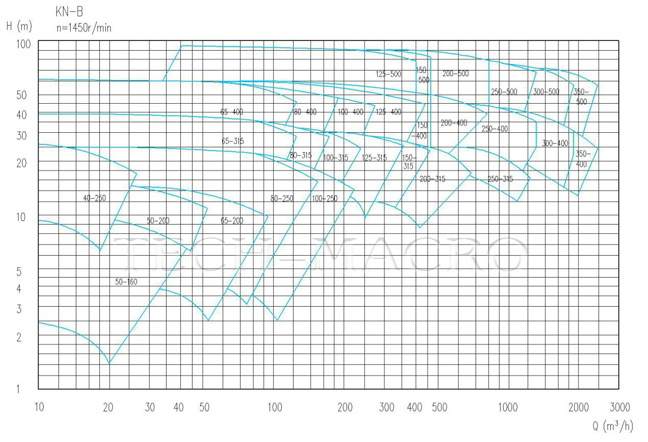

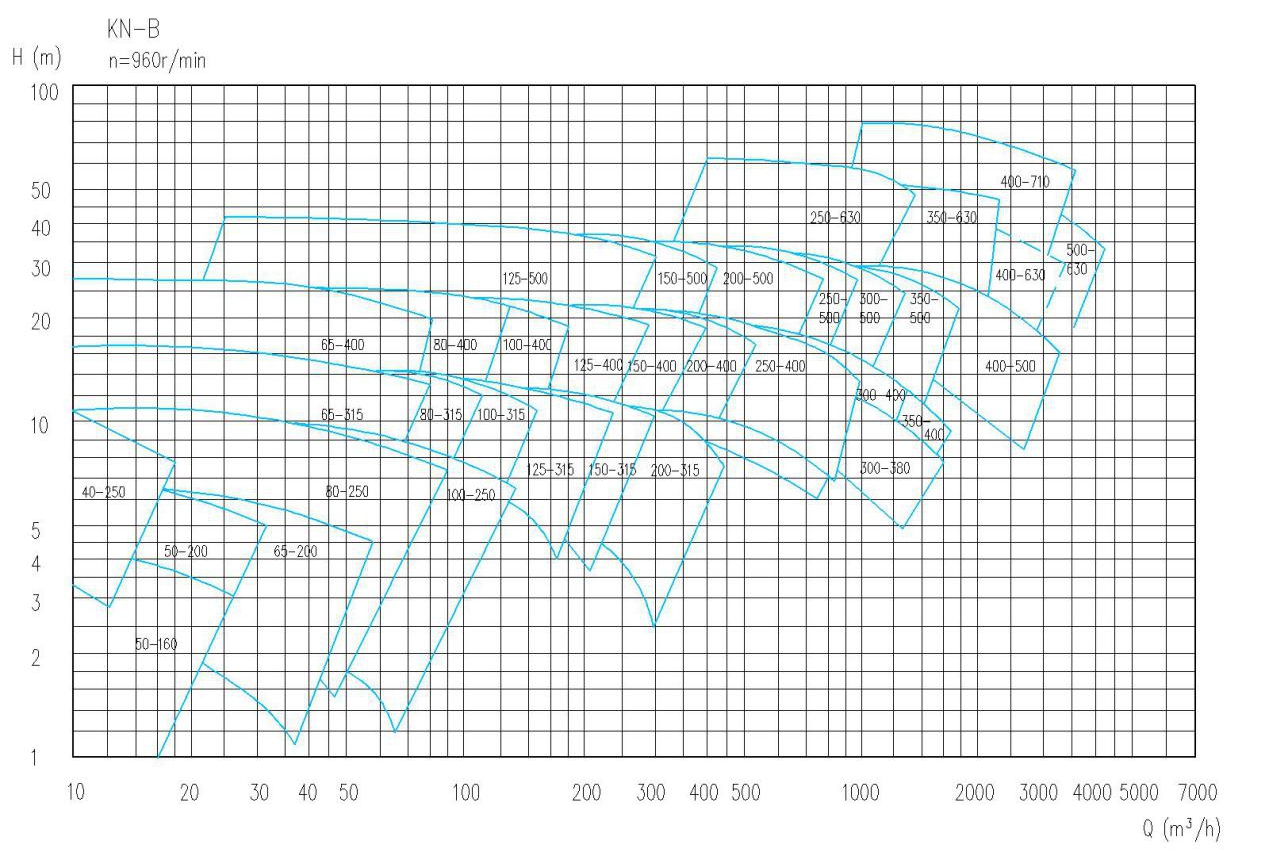

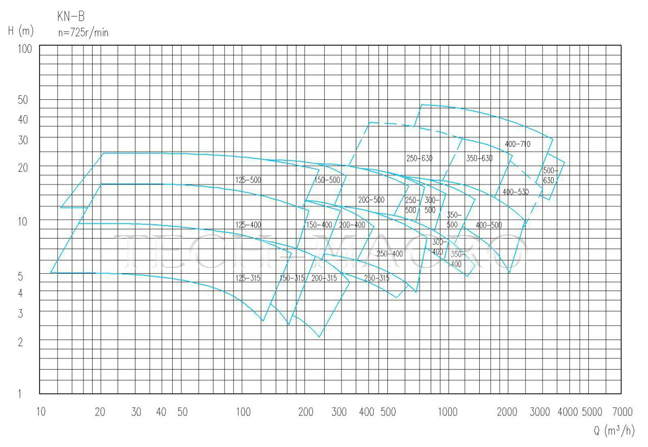

3. Performance Chart:

The below selection chart only show part of KN models. Please freely contact us for more detaied information.

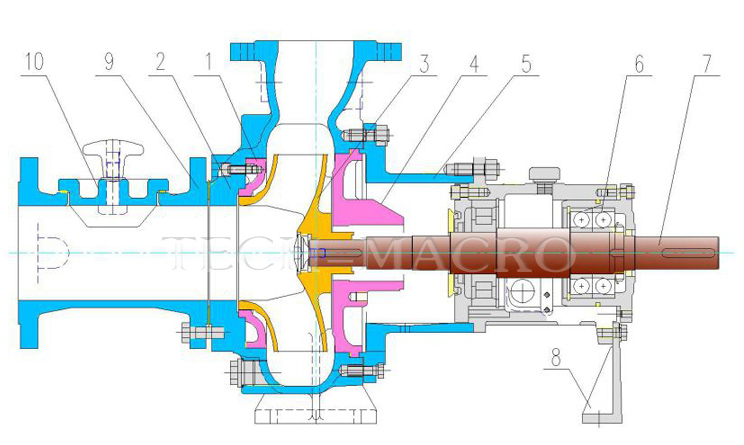

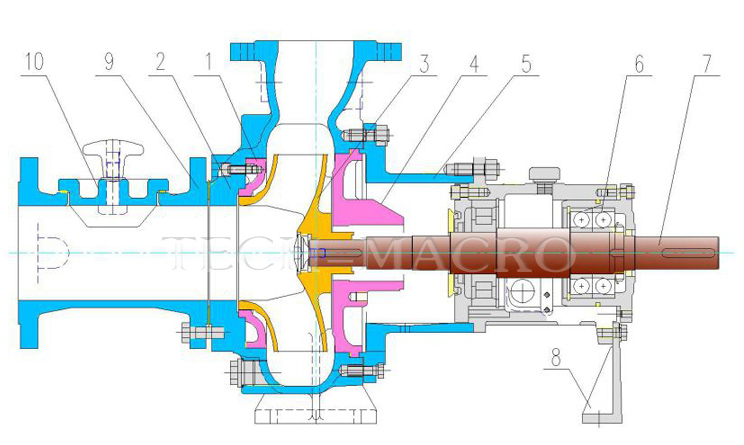

Structure

KN series

1 Wear plate of suction side 2 Pump casing 3 Impeller 4 Discharge cover 5 Jointer 6 Bearing 7 Shaft 8 Support foot 9 Suction pipe 10 Inspection hole |