1. Description:

The type ZGB(P) pump is of horizontal single-stage, single-suction, cantilever, double-casing, centrifugal slurry pump. Among them, the ZGB(P) pumps are for stage 3 or 4 pumps in multi-stages. The pump is suitable for handling abrasive and corrosive slurry, widely used in electric power, metallurgy ,mine, coal, constructional material and chemical industry departments especially for removing ash and sludge in electric power station.

Typical Application:

● Ore processing

● Removing ash and sludge in power plant

●Transferring lime-ash in power plant

● Metallurgy

● Building materials

● Ash removal of sea water

● Salt spray electronic chemistry

● Other anti-abrasive anti-corrosive working conditions

2. Features:

● Large capacity; wide flow channel; high head; high efficiency; energy saving; long service life of wear parts; stable performance; easy maintenance.

● Advanced modern CAD(computer aided design), good hydraulic performance; good performance of NPSH; low wear rate.

● The pump adopted horizontal split oil lubricated bearing, with two sets of cooling system, to ensure the pump operating safely.

● The pump discharge can be positioned to 8 directions at intervals of 45 degree.

● Packing combined expeller and mechanical seal are optional, either of which ensures zero leakage.

● The inlet is horizontal. And the pump runs clockwise viewing from the drive end.

● The wet parts use wear-resistant materials to enlarge service life.

● The pumps can be installed in multi-stages under the allowable max. Pressure, and the max. working pressure allowed is 3.6 MPa.

● The wet parts of the ZGB and ZGBP pumps of same discharge diameter can be interchangeable.

1. Operating Limits

● Discharge Diameter: 65--300 mm

● Flow Capacity:30--2000 m3/h

● Head:25--100 m

● Efficiency(%): 47.4--81.2

2. Materials:

|

Materials Options |

|

Construction |

Standard |

Optional |

|

Wet end parts (Liners,Impellers) |

High chrome alloy (A05, A07, A08, A09, A11, A49, A33, A61……);

Composite ceramics |

The material adopted is usually based on the detailed application, or could be according to the customer’s requirements. |

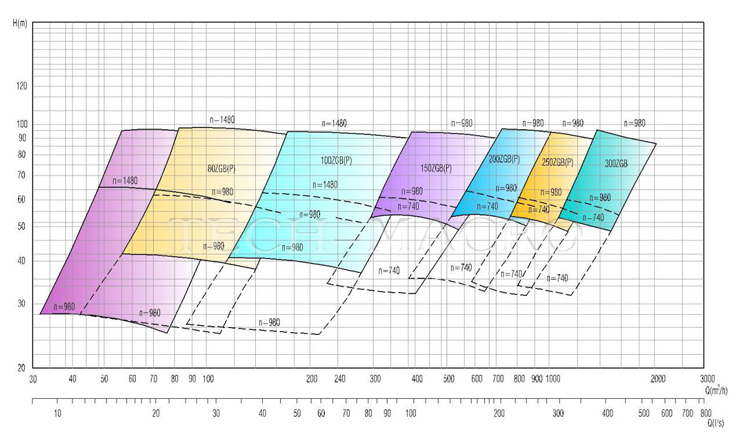

3. Performance Chart:

Note : Approximate performance of clean water and only for primary model choice.

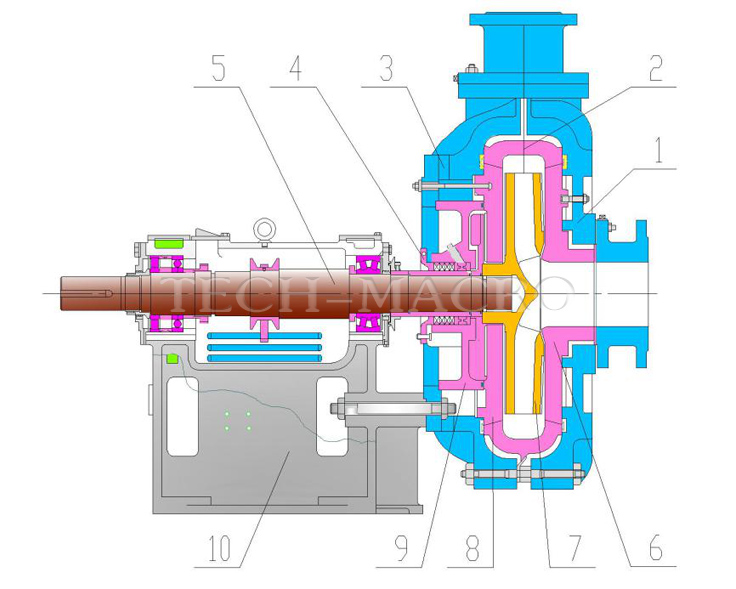

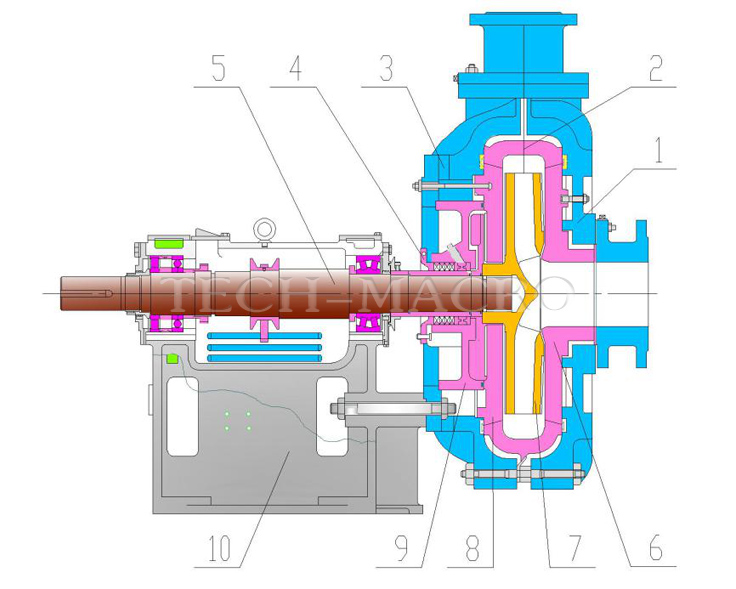

Structure

|

ZGB(P) series

1 Cover Plate 2 Volute Liner 3 Frame Plate 4 Expeller Ring 5 Shaft 6 Throat Bush 7 Impeller 8 Back Liner 9 Seal Box 10 Frame

|